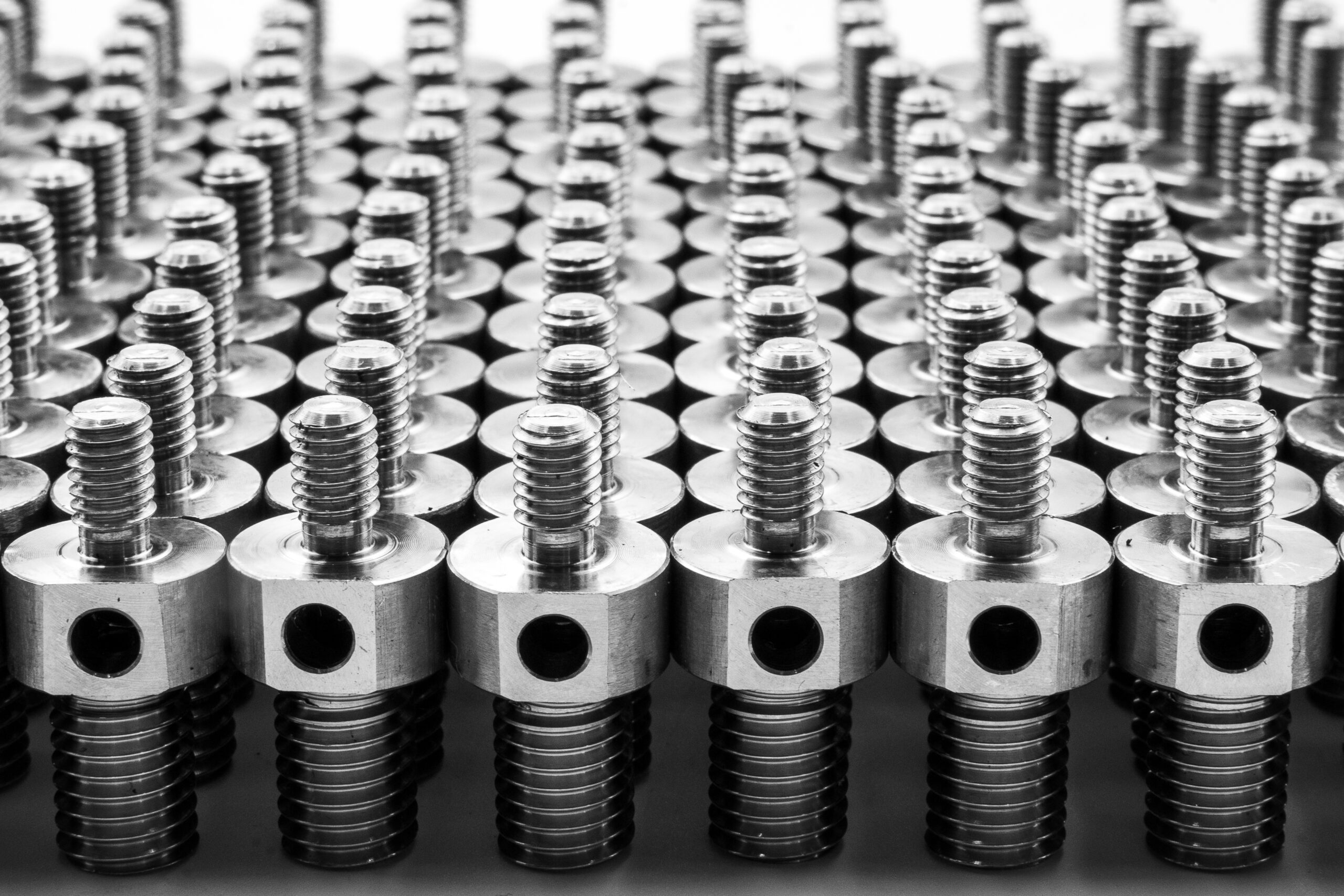

Custom-made screws these are threaded elements used for detachable connections of two or more elements. Their main function is to connect components by means of a threaded connection. The advantage of this type of connection is that components can be repeatedly connected and disconnected without physical damage.

A typical screw consists of a head, a pin, and an external thread. The screw head may have different shapes depending on the application, e.g. hexagonal, mushroom, oval, conical, steeple or flat. Bolt threads may be present along the entire length of the pin or part of it.

Draw bolts come in a variety of sizes, lengths, materials and thread types to suit different applications and design requirements. The most common screws are those with metric threads and those with inch threads. Screws can be right-handed (screws with right-hand threads) or left-handed (screws with left-hand threads).

Custom screws are widely used in construction, automotive, industrial, and home applications. Selecting the appropriate screw, both in terms of its size and properties, is crucial for the durability and safety of the connection.

Special screws are a group of non-standard screws that have been designed and manufactured for specific applications or working conditions. They are used in situations where the use of standardised screws is impossible or difficult due to shape or properties.

Special, drawing screws are characterized by design or functional features that allow them to be used in specific conditions. These types of screws can be made of any material, such as steel, stainless steel, brass, copper, aluminum, bronze or plastic, and take any shape depending on the needs and purpose.

Use of special screws, drawn to size:

Special screws are primarily used when:

| Materials |

steel, stainless steel, brass, copper, aluminium, bronze, plastics |

| Coatings |

no coating, zinc electroplated (ZN), hot-dip electro-plated (TZN) |

|

Additional operations |

hardening |

|

Types of thread |

metric, inch, trapezoidal, fine tread |